Check out our new belt knives!

From its conception, Village Leathers has been all about the belts. Belts are the foundation of our business and belt cutting is one of the most important ways we can make amazing quality leather belts actually affordable. We do things a little differently at Village Leathers. It is important to us to craft only the best quality leather goods, but at the same time, those products need to be affordable. So over the years we have merged man and machine to try and create the most efficient manufacturing methods possible. More on our pricing transparency in another post later! Back to the belts…

When Village Leathers was born, back in the 1970’s, belts were cut one by one with a trusty plough gauge. A straight edge was cut on the edge of a hide with a knife, then the gauge was set to the belt width you wanted and away you plough, pushing the gauge along the edge of the leather. 500 belts later, you’ve got some serious forearm tone.

With the increasing cost of leather, belts needed to be cut much more quickly to keep them affordable. So in 1981 we welcome, the roller press. Still the biggest machine we have here in the workshop, roller presses are used for all kinds of cutting, from leather to cardboard and all kinds of plastic and foam. And what a revelation it was. With big wooden dies, five belts can now be cut in the time taken to cut one.

It has it quirks for sure, you have to place the leather just right to make sure it doesn’t move while you cut it, and re-greasing it is rather a delicate procedure. But in 2019 it is still our preferred way to make belts; we can do it super fast, and we create minimal waste.

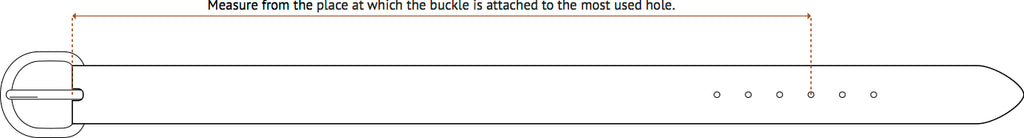

Over the years, legacy has brought up a few issues for us in terms of belt cutting. You may have noticed that your ‘small’ 1” Classic belt fits great, and so does your ‘medium’ 1 ½” Classic belt. It has been a confusing problem for us! After probing Mark as to why this happens, we discovered that the different belt knives were bought over a long period of time and from different companies. This meant that continuity of size was difficult to maintain, and that coupled with ever changing fashions moving our trousers up and down our bodies, created all kinds of questions when it came to sizing.

But we embraced our heritage, (more about that here) and we’ve done our best to work with what we have for as long as possible. However tools don’t last forever, and we’re pretty happy with 30 years worth of belt cutting. FYI that’s more than 2,000,000 belts! After all that cutting, the blades have got chipped and dented in places and so we made that decision to upgrade before the quality started to slip.

So you can see why a complete new set of tools is actually a huge deal for us here making your belts. The day has finally come where a ‘large’ is a ‘large’ in whatever width you fancy!

Something tells me our old tools won’t be going anywhere anytime soon...we can even find reason to use the antique plough gauge every now and again, although mainly for sentimental reasons.

New tools! The belts will still be made with best materials and by hard working craftsmen (or craftswomen). I am the proud owner and wearer or my black classic 1 1/2 worn most days!